![]()

在此处观看有关Greentech Media的网络研讨会。要直接下载网络研讨会幻灯片,请点击这里:NEXTracker:与同行一起,推动太阳能跟踪器风能测试标准的制定

涵盖的主题:

- 了解同行评审过程在提供独立的风洞测试方法和结果验证方面的重要性

- David Banks博士和Girma Bitsuamlak博士关于正确的空气弹性风洞测试方法的验证结论

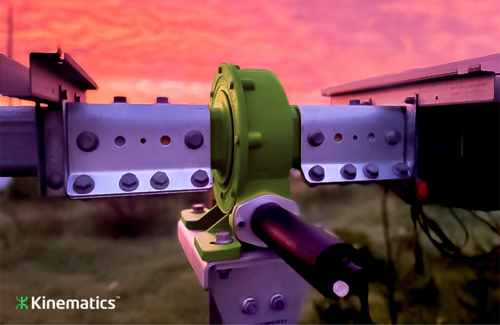

- 检查影响跟踪器结构的主要空气弹性效应

- 强大的2-in-portrait追踪器设计的风风险缓解因素

[NEXTracker]问:您会多久估算出司法管辖区忽略了需要代码的同行评审?

该代码未专门针对单轴跟踪器(SAT),并且出于网络研讨会中概述的原因,倾斜屋顶和桥面板的代码不应应用于SAT。需要风洞测试以解决代码未涵盖的结构。作为最佳实践,我们建议IE和AHJ向知名的风能工程公司寻求风洞分析,并进行第三方同行评审以消除偏见。不遵循此步骤可能会导致类似结构的结果差异很大,并存在风荷载计算不足的风险。

[NEXTracker]问:在太阳能电池阵列的设计载荷中如何考虑动态载荷系数/系数?您能否提供一个有关如何确定负载的示例?

在最简单的形式中,需要将动态放大因子(DAF)和静态系数结合到跟踪器结构和组件的结构计算中。此外,由于跟踪器可以沿其长度方向扭曲,因此需要沿跨度应用不同的系数和因数,以确保符合设计要求。最后,由于风的波动性,跟踪器无论如何都将经历一些扭转变形,这将导致额外的扭矩需求。这是根据空气弹性风洞测试期间测得的加速度估算得出的,应将其添加到静态负载需求中。

[NEXTracker]问:在平均最坏和最好的情况下,每年每瓦因风灾造成的损失成本是多少?

如果风在设计风速范围内,则设计正确的跟踪器每年应遭受零风害。NEXTracker的NX Horizon Gen 2的运行中/正在建设中的GW超过23 GW,在数百个站点中没有发生重大故障或损坏。NX Horizon和NX Gemini都是使用相同的风电工程最佳实践开发的,特别是气动弹性风洞测试,同时充分考虑了所有潜在的动态影响,包括扭转发散,扭转驰豫,颤动和涡旋锁定。

对于没有考虑动态风和其他因素的跟踪器,故障的成本范围很广。

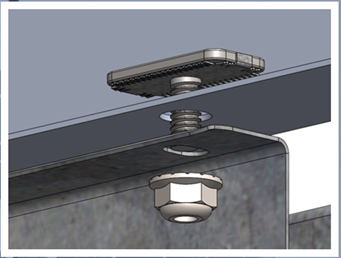

[NEXTracker]问:在安装阻尼组件之前,在施工阶段安装模块会增加哪些风险?

建议先安装风门,因为模块是跟踪器结构上风荷载的驱动力。最佳实践建议仅在安装所有组件之后才放置它们。阻尼器使结构变硬,即使在低风速下也将有助于防止故障。此外,由于将不会调试工厂,因此在工厂开始运行之前应遵循备用的存放做法。

[博士 银行]问:长时间进行的PV站点测得的风速能否代替规范中的风速要求?

通常,不需要,因为要确定50或300年的设计速度需要很多年的数据。但是,可以使用站点的测量结果来确定站点上的风是否存在异常,这些异常可能不会出现在本地机场数据中,例如,方形风(下坡)。

[博士 银行/博士 问:低倾角和高倾角之间的边界是什么?

作用在太阳能板上的空气动力分别由附着的和分离的流动结构以及围绕它的相关压力决定,分别处于低倾斜角和高倾斜角。这些状态之间的边界由失速角定义,该失速角可以从空气动力学扭矩与入射风角的风洞测量中获得。对于低倾斜角范围,空气动力学扭矩随风入射角的增加而增加。边界的特定值(即失速角)取决于跟踪器的几何细节。

[博士 银行]问:如何在有限的风洞宽度中充分测试长组件?

如果装配跨度太大,则可能需要更宽的通道,因为无法将跟踪器做得太小,否则将丢失重要的细节,并且/或者相似性参数(例如质量惯性矩)可能变得无法匹配。

[博士 [Bitsuamlak]问:对于气动弹性仿真,您是否将材料视为纯弹性?也就是说,您是在假设变形较小但允许较大的旋转位移,还是在考虑变形的可能性?柯西或绿色菌株?

对于气动弹性仿真,假定材料具有线性弹性,则可以估算结构的刚度。非线性主要来自气动滞后。

原文:

![]()

Watch the webinar on Greentech Media here. To download the webinar slides directly, please click here.

For those who submitted questions during the webinar, thank you. We’ve compiled your questions and answered them below.

Topics Covered:

- Understanding the importance of the peer review process in providing independent verification of wind tunnel testing methods and results

- Validated conclusions from Dr. David Banks and Dr. Girma Bitsuamlak around proper aeroelastic wind tunnel testing methodology

- Examination of major aeroelastic effects that impact tracker structures

- Wind risk mitigation factors for robust 2-in-portrait tracker design

[NEXTracker] Q: How often would you estimate that the code-required peer review is ignored by jurisdictions?

The code does not specifically address single-axis trackers (SATs), and the code for sloped roofs and bridge decks should not be applied to SATs for the reasons outlined in the webinar. Wind tunnel testing is required to address structures not covered by code. It is our recommendation as a best practice that IEs and AHJs look for wind tunnel analysis from a reputable wind engineering firm, plus a third-party peer review to remove bias. Not following this diligence step can lead to wide variations in results for similar structures, and risk of under-calculating wind loads.

[NEXTracker] Q: How are dynamic loading factors/coefficients taken into account in the design loading of a solar array? Can you provide an example of how this load determination is conducted?

In its simplest form, dynamic amplification factors (DAF) need to be incorporated along with static coefficients to the structural calculations of the tracker structure and components. Furthermore, since the tracker can twist along its length, different coefficients and factors need to be applied along the span to ensure design compliance. Lastly, trackers will undergo some torsional deflection, no matter what, due to the fluctuating nature of the wind that will result in additional torque demand. This is estimated from the accelerations measured during an aeroelastic wind tunnel test and should be added on to the static load demand.

[NEXTracker] Q: What is a ballpark cost per watt for wind damage annually for the average worst- and best-case scenarios?

Properly designed trackers should experience zero damage from wind annually, providing the wind is within design wind speed conditions. NEXTracker’sNX Horizon Gen 2, with over 23 GW operating / under construction, has had no significant failures or damage over hundreds of sites. Both NX Horizon and NX Gemini were developed using the same wind engineering best-practices, specifically aeroelastic wind tunnel testing with thorough consideration of all potential dynamic effects, including torsional divergence, torsional galloping, flutter and vortex lock-in.

For trackers that do not take dynamic wind and other factors into consideration, failures can range widely in costs.

[NEXTracker] Q: What are the increased risks for installing modules during the construction phase prior to the installation of damping components?

It is recommended to install dampers first since modules are the driving force of wind loads on a tracker structure. Best practices suggest that they be placed only after all components have been installed. Dampers stiffen the structure and will help prevent failures even at low wind speeds. In addition, as the plant will not be commissioned, alternate stow practices should be followed prior to the plant becoming operational.

[Dr. Banks] Q: Can measured wind speeds at a PV site, performed over a long period of time, replace the wind speed requirements in the codes?

Generally, no, because so many years of data are needed to determine a 50 or 300-year design speed. However, measurements from a site can be used to determine if there is anything unusual about winds at the site that might not appear in local airport data, such as katabatic (downslope) winds.

[Dr. Banks/Dr. Bitsuamlak] Q: What is the border between a low and high tilt angle?

The aerodynamic forces acting on a solar panel are dictated by attached and separated flow structures and the associated pressure around it, at low and high tilt angles respectively. The boundary between these regimes is defined by stall angle, which can be obtained from wind tunnel measurements of the aerodynamic torque versus wind angle of incidence. For the low tilt angle range, the aerodynamic torque increases with the angle of wind incidence. The specific value for the boundary (i.e. stall angle) depends on the geometric details of the tracker.

[Dr. Banks] Q: How can long assemblies be adequately tested in the limited width of wind tunnels?

If the assembly span is too great, a wider tunnel may be needed because the trackers cannot be made too small, or important details will be missed, and/or similarity parameters (such as mass moment of inertia) can become impossible to match.

[Dr. Bitsuamlak] Q: For the aeroelastic simulation, do you treat the material as purely elastic? That is, are you making a small-deformation assumption but allowing for large rotational displacements or are you accounting for the possibility of large deformation? Cauchy or Green strain?

For aeroelastic simulations, the stiffness of the structure is estimated assuming linear elastic behavior of materials. The nonlinearly is predominantly coming from aerodynamic hysteresis.