尽管双面太阳能电池技术对于光伏并不是新生事物,但最近的进步使该技术在商业上比光伏电厂更具可行性。

然而,随着可行性的发展,在选择双面模块而不是单面模块时,人们对潜在的能源产量和最佳实践提出了疑问 。 尤其是大学研究和其他初步研究表明,从转换为双面模块获得的收益增加了20-30%的可能性–确实是这样吗?

简而言之,没有。

Array Technologies与PV Lighthouse和CFV Solar Test Laboratory合作进行了一项独立研究,评估了 双面太阳能电池在现实世界中的影响。

这项研究的目的是确定对技术进行建模的最佳做法,以便准确了解公用事业规模光伏电站的发电量。通过使用来自CFV的现场数据与PV Lighthouse 的三维射线追踪建模相关联,该研究确定了现实的建模输入。结果提供了可计算的,现实世界中双面电厂的最佳建模方法。

在最近的绿色科技媒体研讨会在此基础上研究了阵列,光伏灯塔和CFV回答有关研究及其发现的常见问题的机会。

网络研讨会问答集锦

如果您错过了网络研讨会,下面是一些亮点以及与会者提出的问题的答案。

下面的答案由Array的 Kyumin Lee(KL), PV Lighthouse的Keith McIntosh(KM) 和CFV的Jim Crimmins(JC)提供。

问: 进口灰色和白色碎石作地面覆盖物以增加反照率在经济上是不现实的。在模拟过程中是否考虑了多种地面覆盖物的可变反射率值?

JC: 对于实验室环境, 最重要的是拥有稳定的反照率。砾石是一个非常稳定的表面,易于控制 的 植被。我们还模拟了具有各种合成表面的更高的反照率。稳定的反照率使我们能够拟合模型,然后将其用于预测不同反照率的产量。最好将现实世界中的反照率视为一个与地点相关的时间序列,该季节随季节变化并且还随降雨和降雪而变化。

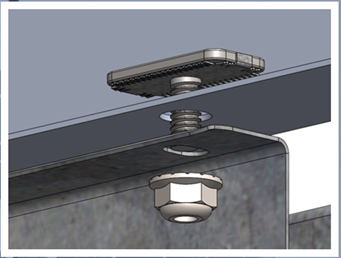

问:SunSolve 是否 考虑使用2MIP并带有扭力管,以避开模块背面或阻塞模块背面?

KM: 具体来说,我们检查了东西模块间隔为16厘米(与扭矩管相同的宽度)的情况。如您所料,这减少了扭矩管的阴影,但是由于需要更大的回溯以避免行到行阴影而抵消了产量的增加。我们发现,包括模块之间的东西向分离会导致产量略低。

问: SunSolve 与Array 之间是否存在当前的合作关系 ?

KM: PV Lighthouse是Array Technologies聘请的独立科学咨询公司和软件提供商,用于进行此项研究的仿真。尽管我们欢迎将来有机会与Array Technologies 合作,但我们之间没有正式的合作伙伴关系。

问: SunSolve 是否 提供有关其建模的任何保证?

KM:SunSolve 准确性的可信度 来自验证研究,例如网络研讨会和发表的论文中介绍的其他 研究。但是,像其他系统仿真软件一样, SunSolve 不能保证将产量预测在一定的精度范围内,因为该精度取决于用户的实验测量结果和对SunSolve 输入的选择 。PV Lighthouse签订了咨询协议,其中将其 SunSolve 模拟和分析应用于有保证的专业科学标准。

问:在低反照率值下结果是否一致?

KM:随着反照率的降低,1MIP相对于2MIP的相对优势也随之降低。这种趋势的原因是1MIP到2MIP的光学优势属于后侧光学器件(用于测试配置)。

问: d OES增益阵列间距的函数而变化?

KL:是的,当系统不回溯时。但是视野因子并不会随地面覆盖率(GCR)成比例增加,因此在经济学上存在一个交叉点。

问: 边缘是否有虚拟模块?在那种情况下,您不会降低热点和旁路二极管激活的可能性吗?

KL: 有w ^ ê 重新哑模块北端。当地面辐照度成法线角度时,电池失配在南端最大。

问:双方的效率是多少,综合效率是多少?

KL:根据 IEC TS 60904-1-2测量光伏组件的 双面性。基本上,标准测试条件在背面的峰值功率/标准测试条件在正面的峰值功率。在建模中,您不会对正面,背面和集成使用不同的效率。模块效率保持恒定,并且是要计算的总有效辐照度。总有效辐照度=阵列辐照度的正面+ 双面性 *阵列辐照度的背面。

问:实际上可以从中吸收多少漫射辐射?

KL:那完全 取决于气候。在美国各地,年度扩散分数(扩散水平辐照/整体水平辐照)可以在0.2到0.5之间变化。

问:在季节性基础上找出双面系统反照率值的最佳方法是什么?

KL:最佳做法是在现场进行一年的实际反照率测量。一个后备解决方案将是使用各种基于卫星的服务(例如PVGIS)估算的反照率值。

问: 对于Array2的模块,应用了哪些技术?N型Topcon,PERT还是HJT?

KL: n-PERT 。

问: 什么是 的 区别 一lbedo和 d iffuse分数?

KL: “反照率”是地面的反射率。“散射分数”是不直接来自太阳的阳光的分数。例如,一些阳光在到达面板之前就从云层反射出来;阳光有助于扩散。在无云的日子中,扩散比例约为10%,在完全阴天时,扩散比例为100%。

问: 我可以看到1MIP和2MIP之间的遮光损失 是 相似的。但是假设在2MIP中顶部模块和底部模块之间没有间距。但是, 实际上,在2MIP中它们之间存在差距。

KL: 对于具有固定阵列行间距的2MIP设置,模块之间的零间隙将为您提供更多能量。在模块之间留有空隙的2MIP配置在经济上并不可行。延长回溯所带来的能量损失要比减少阴影损失所获得的任何能量收益都多。

问:双面测量与PVsyst的误差范围是多少?

KL:确实取决于每种情况。当前,不确定性的最大来源是(1)模块特性和(2)反照率。如果知道这些,PVsyst针对给定天气数据计算出的能量的准确度可以大大低于0.5%。

问: 我于2008年在南极安装了第一个太阳能系统, 并且可能会在未来 五年 内重新使用。 如果我要垂直于地面安装双面模块,那么当太阳处于相同的角度和强度时,我会在12小时后从模块中获得相同的输出吗?基本上,如果我将模块倒置安装,输出会有什么不同?

KL: 这取决于模块的 双面性。广泛使用的双面组件为双面组件的65%,因此在相同的辐照度下,背面将少产生约35%的组件。有些模块的双面超过70%(例如LG n型)。

问:您可以分享CFV设置的PVsyst模型中使用的建模假设吗?(阴影损失,透明度,不匹配等)

KL:类型2(透明底片 n-PERT)的透明度设置为2.5%,类型1(白色底片polyPERC )的透明度设置为 0 。

问: CFV是否要建立2MIP测试设置?

JC: 尚无计划, 但我们愿意接受。

问:模型中是否考虑了阴影强度?它对结果有多大影响?

KC: 是的,已考虑在内。我们没有专门检查其在项目中的贡献。

问: 测试场的照片不包含任何2MIP行。你部署/测量2MIP RPOA和Bi ˚F acial增益在CFV试验现场?

KL: 测试不包括2MIP跟踪器。我们的方法是通过在1MIP跟踪器上进行测试来增强对3D射线跟踪和2D视图因子建模(PVsyst)的信心,然后将射线跟踪和建模扩展到2MIP情况。

问: 您是否打算以后根据经验验证2MIP模型?

KL: 我们目前没有任何计划。我们将让我们的2MIP竞争对手提供类似质量的现场测试结果!

问: 所描述的光线跟踪软件能否处理复杂的地形应用, 例如东北部起伏的地形?

KM: SunSolve 目前假定地形平坦。

问:我们已经使用GCR表征POA提升了。 我ntroducing行高度为双面效应的正交度量可调谐的,但如果已经使用GCR宽度与高度的比率是多余的。

KL: 我完全同意。我们只是想揭穿一个事实,那就是更高的行更好, 无论如何。

问: 测得的反照率为30%,理想值为24%。 Ç 一个我们信任的测量导致好的模拟?

JC: 模型预测双面增益结果与该类型范围内的反照率非常线性。 因此 很容易扩展它们。

问:为了增加反照率和扩散分数,构建双面SAT的最佳平台组成是什么?

KL:反照率为0.3时,双面增益将在5-10%的范围内。如果 单面 系统的产量为100,则双面系统的产量为105到110。您可以通过反射性更强的地面覆盖使其达到〜115 ,但是我不确定这是否真的值得。

问: 您考虑的2个MIP 系统是否考虑了在模块之间装有扭矩管的机架系统,因此(可能) 模块 背面没有直接的后部遮光板?

KL: 由于您回溯的时间越来越长,因此2MIP跟踪器上扭矩管的东西向间隙实际上减少了能量产生。2MIP跟踪器的最佳策略是没有任何差距。

问: 在雪地里做过任何测试吗?

KL: CFV用白色反光篷布模拟雪况。

问:反照率对双面模块的性能有多大影响?

KL:反照率对双面收益影响最大。一个在反照率〜0.3的地面覆盖上产生〜5%双面增益的系统将在〜0.6的反照率的地面覆盖上产生〜10%双面增益。

问:阴影 对1MIP和2MIP 有多大 影响?这对1MIP相对于2MIP的捕获率优势有负面影响吗?

KL:2MIP跟踪器可以通过具有东西向模块间隙来实现较低的遮光损失因子,但这实际上会减少年产量,因为间隙会增加GCR,从而导致更长的回溯。回溯增加所带来的能量损失要比阴影系数较低所带来的任何收益都要多。 因此 ,2MIP的最佳策略是模块之间不要有任何缝隙。当没有模块EW间隙时,2MIP跟踪器的阴影损失与1MIP跟踪器的阴影损失没有太大差异。

问: MIP跟踪器是什么意思?

KL:1MIP =纵向一个模块。2MIP =纵向两个模块。

问:您是否说双面模块最适合特定的地理位置,以获取最大的能量收益?

KL:不,我认为双面系统在大多数地区都有意义。

问:双面模块在双轴跟踪器上是否能很好地从“边缘效应”中获取更多的反照率?

KL: 是的,他们会在某种意义上。但是仅双面就不足以证明两轴跟踪器是合理的。

问: 对于PR测试,您会多久放置一次反射计或日光计来测量背面辐照度?考虑到背面辐照度的均匀性较弱,您认为在PR休息期间背面辐照度测量与正面辐照度相比有多少不确定性 ?

JC: 这是一个复杂的问题。在此项目中,我们没有测量小面积的背面辐照度。我们使用了总辐射表。小面积背面辐照度最好通过建模来处理。

问:对“ PVSyst ”中的“失配损耗” 有何想法?

KL:我们从射线追踪和SPICE模型确定的失配损耗因子小于PVSyst 通常建议的失配损耗因子 ,部分原因是地面反射的射线以高角度入射,从而产生柔和的阴影。

问: 1MP和2MP的比较 – 这是否会在PVSyst中自然 出现, 还是需要在设置中更改一些损耗?

KL: 如果您为1MIP和2MIP跟踪器使用标称配置,这将自然而然。

问: 导线管理如何影响 双面 收益?

KL: 布线管理很重要,在CFV测试中, 要格外小心,以确保布线阴影不是重要因素。我们计划在不久的将来提供公用事业规模的解决方案。

问: PV Lighthouse是否考虑了CFV现场测试的不同PV组件的光谱响应?

KM: 是的。使用公开的光谱模型估算了来自太阳的入射光谱,从NASA数据库获取了地面(和扭矩管)的光谱反照率,并通过射线追踪和设备仿真确定了模块的光谱响应。

问: 由于纵横比的增加,回溯算法将如何改变(如果有)?

KM: 回溯算法不会改变。你还想要捕捉的 最淡的 正面上directl Ÿ 没有苦难行到行阴影。

问:w ^ 帽子 的 你体验差 在 N-二PERT&P-PERC双面的表现?

KL: n-PERT模块的 双面性在70-75%的范围内。 p-PERC模块的 双面性在65-70%的范围内。我们测试的n-PERT模块也具有较高的串联电阻和较低的温度系数,这也有助于提高能量产量。

问:什么是我MPAC B的牛逼ifacial模块 小号elf- 小号哈丁对性能/产品的健康呢?

KL: 我不知道双面模块的任何自阴影。

问: 您在1P和2P模拟中是否使用了相同的GCR,如果是, 则宽高比 和丢失到天空的光线是否相同?

KL: 是的,我们在1P和2P模拟中都使用了35.1%的GCR。对于1MIP,扭矩管的高度设置为1.6 m,对于2MIP,扭矩管的高度设置为2.4 m(这是商用系统的典型值)。由于2 MI P配置 的模块长度是模块长度的两倍,而模块 高度则不是模块 高度的两倍,因此它具有较低的长宽比,因此更多的光丢失到了天空。

问: 如何通过b 社交模块找到性能比 ?

KL: 我们没有使用性能比率。我们计算了双面和单面 阵列的每日特定产量, 并比较了这些值以计算双面收益。

问: SunSolve 用什么编程语言 编写?

KM: SunSolve 可通过Web浏览器访问,其用户界面用HTML和Javascript 编写 。SunSolve的 计算引擎在云中运行;其中大部分是在Csharp中编程的 。

问: 你能覆盖最大电流的比计算 升uminescent太阳能集中器中使用的 monofacial 模块。

KL: 我建议看的每小时总和 GlobInc 和 GlobBak 在PVsyst值最大有效辐照度估计到模块和缩放前侧 升uminescent太阳能集中因此,与一些考虑温度系数。

问: 与逆变器模块并联的双面电池串的电池串电流是否受电流不匹配限制为每个电池串上的最低模块电流? 那么 短跟踪器的末端边缘效果增益没有实现吗?

JC: 边缘效果会增加一些 产量, 但是 会因长串不匹配而降低。在非常短的字符串中或单独测量时, 它们更为重要。

问: 剪裁怎么样?W¯¯ Hat的优选的AC / DC比?

KL: 我建议进行PVsyst +经济学研究,以确定最佳的DC:AC比。我的第一个猜测是名义上的 单面 DC:AC比值减去预期的(未截断的)双面增益。

问: 是否对任何2MIP安排进行了物理测试,或者仅是模型化?

KM: 在这项研究中,仅对2MIP安排进行了建模。PV Lighthouse将在2020年7月的IEEE PVSC上提交有关2MIP配置测量的论文。

问: 为什么基思的研究中1 MIP的反照率参数与2 MIP的反照率参数不同?我相信这是0.240 vs 0.236 。

KM: 在1MIP和2MIP配置的光线跟踪中使用了相同的反照率。这是波长的函数表示棕色, 壤质土。然后使用射线追踪的结果确定最佳值,以用作PVSyst 中代表相同土壤的反照率因子 ,您是对的,实际上2MIP(0.236)的确比1MIP(0.240)的稍低。这表明在一年中,2MIP配置使用的地面反射光比1MIP配置使用的略少(考虑了波长,漫射/直接比以及假定的天气状况)。我们希望这些值会随着反照率,模块类型和条件的变化而变化。

问: 是 访问SunSolve 已经提供给模拟BIFA 官方 系统?模拟的确切输出是什么?

KM:是的。有两种方法可以使用SunSolve 模拟双面系统 。

(1)在合同基础上,PV Lighthouse执行模拟(如本研究中所述)。

(2)在订购的基础上,您可以执行仿真以确定(i )在单个时间点的输出功率和详细损耗,以及(ii) 在任何时间段(2020年7月可用)的产量,损耗和 PVSyst 输入。

电子邮件support@pvlighthouse.com.au了解更多详情。

问: PV Lighthouse是否模拟了2个MIP配置以生成与1个MIP类似的PVsyst输入?

KM: 是的。有关2MIP配置的结果,请参阅网络研讨会的幻灯片26 ,标题为“ SunSolve –确定 PVSyst 输入”, 以及与该网络研讨会相关的白皮书。

问: 您能否再次快速说明在1 MIP配置与2 MIP配置下扭矩管遮蔽是否显着?

KL: PV Lighthouse发现2MIP和1MIP的结构阴影损失没有太大差异。我们研究了无间隙情况,因为我们发现,带有模块间隙的2MIP配置与因减少结构阴影而获得的任何能量收益相比,由于长时间回溯而遭受的损失更大。

问:我是否有任何方法或已发表的文章可以在现场测量双面收益?

KL: 没有标准化的方法。我们通过首先计算双面阵列和单面 阵列的每日特定收益率并查看它们的比率来计算双面收益 。

问: 是否需要在工厂的性能比计算中包括背面辐照度?

KL: 柏溪, 与NREL一起, 建议的能力,2019年双面系统的测试出版物都可以找到相关的修改 在这里。

问: 什么是确定月度反照率值的良好资源?

KL: 最佳做法是在现场进行一年的实际反照率测量。一个后备解决方案将是使用各种基于卫星的服务(例如PVGIS)估算的反照率值。NSRDB还提供反照率值。

问: 是否假定地面反射光具有朗伯分布?

KM: 是的,在这项研究中,假定地面反射光是朗伯型的。( 如果感兴趣,SunSolve 可以模拟替代散射函数)。

问: 在哪里可以获取这些光线跟踪派生的输入以运行PVsyst模拟?

KM: PVSyst 输入的结果 在网络研讨会的幻灯片26上,并且也在白皮书中给出。这些结果特定于特定站点(在西德克萨斯州)和系统配置。 可以使用SunSolve 确定其他站点和配置的PVSyst 输入 。

问: 你们都建议在哪里放置反射计和背面POA传感器以最准确地表示整个阵列?

JC: 这取决于确切的部署方案以及站点上反照率的可变性。

问: 许多双面模块制造商的规格或数据表都包括高达25%或30%的背面增益。听起来现实上实际的“平均”或现实世界的背面增益将接近10%?

KL:接近5%。

问: 单面组件的平均生产收益是多少?

吉隆坡:5-10%是一个不错的估计。

问:为什么扩散率高的事件不能转化为发电量的增加?

KM:扩散分数的增加导致入射到模块后侧的辐照度增加,但入射到前侧的辐照度降低。这就是为什么扩散分数增加导致双面增益增加的原因。但是,从后方获得的优势要比从前部获得的优势更为重要,除了一些罕见的例外,例如在今天很晚的回溯期间。

问: 考虑到与1MIP相关的额外机架和建筑成本,相对于2MIP而言1MIP的收益是不是洗礼还是负面的情况?

KL: 我们认为2MIP跟踪器还太新,无法准确了解相关成本。

问: 在使用MIP1诉总追踪器成本(使用MIP2设计时推测较少)的双重生产增加的情况下,MIP1诉MIP2的经济性是什么?

KL: 我们认为2MIP跟踪器还太新,无法准确了解相关成本。

问: 在商业低坡度屋顶或住宅金属屋顶屋顶应用上有什么工作吗?

KL: 不, 这不是我们产品服务的应用程序。

问: CFV实验室能否发布 幻灯片15中介绍的用于分析的 PVSyst 模型?

KL:不。

问: 双面增益驱动因素对站点位置的依赖性如何?这些关系在美国东北部和西南部是否同样适用?小号。?

KL: 很复杂。是的, 您会看到东北部的收益比西南部的收益更高,但是西南部的实际产生的额外能源(以千瓦时为单位)将仍然更高。

问: 是推荐PVsyst“地上高度” 一个 适合基于所述纵横比和测量双面增益?所有地点都适用吗?

KL: 该研究为开展 W¯¯ EST得克萨斯位置。我想你会发现在其他地方类似的结果, 也是如此,但敏感性可能不同。

问: 您的测试是否考虑了电池温度?

JC: 我们假设模块处于相同温度。

问: 不PV灯塔仅模拟器上ë 硅电池, 或可以将其用于薄膜的d /或多结电池?

KM: 从理论上讲, SunSolve 可用于模拟薄膜和多结电池, 但目前面向硅电池。

问: 没有测试模块具有在明显的差距 的 中间 的 模块,从而光命中 的 扭矩管和反弹?还是细胞之间有玻璃?

KL: n型模块在电池之间有明显的间隙,但它们是全电池模块。p-PERC半电池模块没有明显的间隙。

原文:

Field Testing Meets Modeling: Validated Data on Bifacial Solar Performance

Though bifacial solar cell technology is not new to PV, recent advances have made the technology more commercially viable than ever before for PV power plants.

Along with that viability, however, come questions about the potential energy yield and best practices when choosing bifacial modules over their monofacial counterparts.

In particular, university research and other preliminary studies of the increase in gain from a switch to bifacial modules suggested a bump of 20-30% was possible – but is that really the case?

In short, no.

Array Technologies partnered with PV Lighthouse and CFV Solar Test Laboratory to conduct an independent study assessing the real-world impact of bifacial solar cells.

The study’s goal was to determine best practices for modeling the technology in order to get an accurate view of a utility scale PV plant’s power production. By using field data from CFV correlated by three-dimensional ray tracing modeling from PV Lighthouse, the study determined realistic modeling inputs. The results present bankable, real-world modeling best practices for bifacial power plants.

The recent Greentech Media webinar based on this research gave Array, PV Lighthouse and CFV the chance to answer common questions about the study and its findings.

Webinar Q&A Highlights

If you missed the webinar, below is a look at some of the highlights as well as answers to questions which were submitted by attendees.

Answers below were provided by Array’s Kyumin Lee (KL), PV Lighthouse’s Keith McIntosh (KM) and CFV’s Jim Crimmins (JC).

Q: Importing grey and white gravel for ground cover to boost albedo gain is economically unrealistic. Were multiple ground cover types considered during the simulation for variable albedo values?

JC: For a lab environment, the most important thing is to have a stable albedo. Gravel is a very stable surface and easy to control for vegetation. We have simulated higher albedos with various synthetic surfaces as well. A stable albedo allows us to fit models which can then be used to predict yields with varying albedos. It is best to think of albedo in the real world as a site-dependent time series, changing seasonally and also with precipitation and snow.

Q: Did SunSolve consider 2MIP with a torque tube that avoids the backside of the module or obstructs the backside of the module?

KM: Specifically we examined the case when the east-west module separation was 16 cm (the same width as the torque tube). As you’d expect, this led to less shading from the torque tube, but the resulting increase in yield was counteracted by the need for greater backtracking to avoid row-to-row shading. We found that including an east-west separation between modules led to a slightly lower yield.

Q: Is there a current partnership between SunSolve and Array?

KM: PV Lighthouse is an independent scientific consultancy and software provider that was engaged by Array Technologies to conduct simulations for this study. While we welcome the opportunity to work with Array Technologies in the future, we don’t have a formal partnership.

Q: Does SunSolve offer any guarantees regarding their modeling?

KM: Confidence in SunSolve’s accuracy is gained from validation studies, such as that presented in the webinar and others described in published papers. However, like other system-simulation software, SunSolve is not guaranteed to predict yield to within some level of accuracy, because that accuracy depends on the user’s experimental measurements and selection of SunSolve inputs. PV Lighthouse enters consulting agreements in which its SunSolve simulations and analysis are applied to a guaranteed professional scientific standard.

Q: Were the results consistent at low albedo values?

KM: As the albedo decreases, the relative advantage of 1MIP over 2MIP also decreases. The reason for this trend is that the optical advantage of the 1MIP to 2MIP pertains to the rear-side optics (for the tested configurations).

Q: Does gain vary as a function of array spacing?

KL: Yes, when the system is not backtracking. But the view factor does not increase proportionally with the ground cover ratio (GCR), and so there is a crossover point in terms of economics.

Q: Did you have dummy modules at the edges? In that case, wouldn’t you have reduced the likelihood of hotspots and bypass diode activation?

KL: There were dummy modules at the north end. The cell mismatch is greatest at the south end when the ground irradiance comes at normal angles.

Q: What are the efficiencies of each side, and the total, integrated efficiency?

KL: The bifaciality of a PV module is measured per IEC TS 60904-1-2. Basically, Standard Test Conditions peak power on backside / Standard Test Conditions peak power on frontside. In modeling, you do not use different efficiencies for the front, back and integrated. The module efficiency stays constant, and it is the total effective irradiance that gets calculated. Total effective irradiance = Frontside Plane of Array irradiance + Bifaciality * Backside Plane of Array irradiance.

Q: How much diffuse irradiance is actually there to draw from?

KL: That is totally climate-dependent. Across the U.S., the annual diffuse fraction (diffuse horizontal irradiation / global horizontal irradiation) can vary from 0.2 to 0.5.

Q: What’s the best way to figure out the albedo values for a bifacial system on a ground with seasonality?

KL: The best practice would be to make an actual albedo measurement at the site over a year. A fallback solution would be to use albedo values as estimated by various satellite-based services, such as PVGIS.

Q: For module for Array2, what tech is applied? N-type Topcon, PERT or HJT?

KL: n-PERT.

Q: What’s the difference between albedo and diffuse fraction?

KL: The “albedo” is the reflectance of the ground. The “diffuse fraction” is the fraction of sunlight that does not come directly from the sun. For example, some sunlight reflects from clouds before it reaches the panels; that sunlight contributes to the diffuse fraction. On a cloudless day, the diffuse fraction is about 10%, and on a fully overcast day, the diffuse fraction is 100%.

Q: I can see that shading loss between 1MIP and 2MIP is similar. But there is assumption that there is no spacing between top and bottom modules in 2MIP. But, in reality, there is gap between them in 2MIP.

KL: For a 2MIP setup with fixed array row spacing, having zero gap between the modules will give you more energy. A 2MIP configuration with a gap between the modules is just not an economically viable setup. You lose more energy from prolonged backtracking than any energy gain from reduced shading loss.

Q: What is the margin of error for the bifacial measured versus PVsyst?

KL: It really depends on each case. Currently, the biggest sources of uncertainty are (1) module characteristics and (2) albedo. If these are known, the accuracy of the energy calculated by PVsyst for a given weather data can be well below 0.5%.

Q: I installed my first solar system at the South Pole in 2008, and I will likely go back sometime within the next five years. If I were to mount bifacial modules perpendicular to the ground, would I get the same output from the module 12 hours later when the sun is at the same angle and intensity? Basically, what would the difference in output be if I mounted the module upside down?

KL: It depends on the module bifaciality. Widely available bifacial modules are 65% bifacial, and so the back side will produce about 35% less for the same irradiance. There are modules that are more than 70% bifacial (LG n-type, for example).

Q: Can you share the modeling assumptions used in the PVsyst model of the setup at CFV? (shade Loss, transparency, mismatch, etc.)

KL: The transparency was set to 2.5% for the Type 2 (clear backsheet n-PERT), and 0 for the Type 1 (white-backsheet polyPERC).

Q: Is CFV going to build a 2MIP test setup?

JC: No plans yet, but we are open to it.

Q: Is shadow intensity taken into account in the models? How much impact does it have on the results?

KC: Yes, it is taken into account. We didn’t examine its contribution specifically in the project.

Q: The photo of the test yard did not include any 2MIP rows. Did you deploy/measure 2MIP RPOA and Bifacial Gain at the CFV test site?

KL: The testing did not include 2MIP trackers. Our approach was to gain confidence in 3D ray tracing and 2D view factor modeling (PVsyst) via testing on our 1MIP tracker, and then extend the ray tracing and modeling to 2MIP cases.

Q: Do you intend to validate the 2MIP model empirically at a later date?

KL: We don’t have anything planned at this moment. We’ll leave it up to our 2MIP competitors to provide field testing results of similar quality!

Q: Can the described ray trace software handle complex terrain applications, such as undulating terrain in Northeast?

KM: SunSolve currently assumes flat terrain.

Q: We already use GCR in characterizing POA boost. Introducing row height is an orthogonal metric that can tune for bifacial effects, but the ratio of width to height is redundant if GCR is already used.

KL: I completely agree. We just wanted to debunk the myth that higher rows are better, no matter what.

Q: The measured albedo was 30%, the ideal value is 24%. Can we trust measurement to lead to good simulations?

JC: Models predict that bifacial gain results are very linear with albedo within that type of range. So it is easy to scale them.

Q: What is the optimal platform composition for building bifacial SAT’s over in order to increase albedo & diffuse fraction?

KL: The bifacial gain will come in the range of 5-10% for albedo of 0.3. If a monofacial system’s production is 100, the bifacial system will produce 105 to 110. You can get it to ~115 with more reflective ground cover, but I’m not sure if it’s really going to be worth it.

Q: Did the 2MIP system you considered take into account a racking system with the torque tube between modules so (there would be) no direct rear shading on the back of the module?

KL: East-west gap over the torque tube on 2MIP tracker actually reduces the energy production, because you backtrack more and longer. The best strategy for 2MIP tracker is to not have any gap.

Q: Any testing done in the snow?

KL: CFV simulated snow conditions with a white reflective tarp.

Q: How much impact does albedo have on the performance of the bifacial modules?

KL: The albedo has the biggest effect on the bifacial gain. A system that generates ~5% bifacial gain on ground cover of albedo ~0.3 will generate ~10% bifacial gain on ground cover of albedo ~0.6.

Q: How much does shading affect 1MIP vs 2MIP, and does that negatively affect the capture ratio advantage 1MIP has over 2MIP?

KL: 2MIP trackers can achieve lower shading loss factor by having east-west module gap, but this will actually reduce annual production, because the gap increases the GCR, resulting in longer backtracking. The energy loss from increased backtracking is more than any gain from the lower shading factor. So the best strategy for 2MIP is to not have any gap between the modules. When there isn’t any module EW gap, the shading loss of a 2MIP tracker is not too different from that of a 1MIP tracker.

Q: What does MIP tracker mean?

KL: 1MIP = One module in portrait. 2MIP = Two modules in portrait.

Q: Would you say that bifacial modules are best suited to specific geographic locations in order to get the most energy gain?

KL: No, I think bifacial systems generally make sense in most regions.

Q: Would bifacial modules do well on dual axis trackers to pick up more albedo from “edge effects?”

KL : Yes, they would in a sense. But bifacial alone is not enough to justify two-axis trackers.

Q: For PR testing, how frequently would you place albedometers or pyranometers measuring backside irradiance? How much uncertainty do you think would be on backside irradiance measurements during PR resting compared to frontside irradiance, considering less homogeneous nature of the backside irradiance?

JC: This is a complicated question. We did not measure small area backside irradiance in this project. We used pyranometers. Small area backside irradiance is probably best handled through modeling.

Q: Any thoughts on ‘mismatch loss’ to be applied in PVSyst?

KL: The mismatch loss factors that we determined from the ray tracing and SPICE model are smaller than what has typically been suggested for PVSyst, partly because the ground-reflected rays come in at high angles, creating soft shadows.

Q: The 1MP and 2MP comparison – will this come out naturally in PVSyst, or do some losses need to be changed in the settings?

KL: This will come naturally if you use the nominal configurations for 1MIP and 2MIP trackers.

Q: How does wire management impact bifacial gain?

KL: Wiring management is important, and in the CFV testing, a lot of care was taken to make sure that the wiring shading was not a significant factor. Offering a utility-scale solution is something we plan to do in near future.

Q: Did PV Lighthouse account for the spectral response of the different PV modules tested at the CFV site?

KM: Yes. The incident spectrum from the sun was estimated using published spectral models, the spectral albedo of the ground (and torque-tube) was taken from a NASA database, and the spectral response of the modules was determined from ray tracing and device simulation.

Q: How would the backtracking algorithm change, if any, due to gains in aspect ratios?

KM: The backtracking algorithm would not change. You still want to capture the most light on the frontside directly without suffering row-to-row shading.

Q: What is the difference you experience in performance of N-PERT & P-PERC bifacial?

KL: The bifaciality of an n-PERT module is in the 70-75% range. The bifaciality of a p-PERC module is in the 65-70% range. The n-PERT module we tested had higher series resistance and lower temperature coefficient too, which also helped the energy yield.

Q: What is the impact of bifacial module self-shading on performance/product health?

KL: I’m not aware of any self-shading of bifacial modules.

Q: Did you use the same GCR for the 1P and 2P simulation, and if so, would the aspect ratio and light lost to the sky be the same?

KL: Yes, we used a GCR of 35.1% for both 1P and 2P simulations. The height of the torque tubes was set to 1.6 m for 1MIP and 2.4 m for 2MIP (which are typical of commercial systems). Since the 2MIP configuration has two times the module length but not two times the height, it has a lower aspect ratio, and hence more light is lost to the sky.

Q: How is performance ratio found with bifacial modules?

KL: We did not use performance ratio. We calculated daily specific yields of the bifacial and monofacial arrays and compared these values to calculate the bifacial gain.

Q: What programming language is SunSolve written in?

KM: SunSolve is accessed through a web browser and its user interface is written in HTML and Javascript. SunSolve’s computational engine runs in the cloud; much of it is programmed in Csharp.

Q: Can you cover the calculation of maximum current over the luminescent solar concentrator used in monofacial modules.

KL: I’d recommend looking at hourly sums of GlobInc and GlobBak values in PVsyst to estimate the maximum effective irradiance into the module, and scale the frontside luminescent solar concentrator accordingly, with some consideration for the temperature coefficient.

Q: Are the string currents of a bifacial string in parallel to inverter block limited by current mismatch to the lowest module current on each string? So the edge effect gain on the ends a short tracker are not realized?

JC: The edge effects will add some incremental yield, but will be reduced by mismatch in a long string. In a very short string or measured individually, they are more important.

Q: What about clipping? What’s the preferred AC/DC ratio?

KL: I recommend carrying out PVsyst + economics studies to determine the optimum DC:AC ratio. My first guess would be nominal monofacial DC:AC ratio minus the expected (unclipped) bifacial gain.

Q: Were any 2MIP arrangements physically tested, or was that solely modeled?

KM: In this study, the 2MIP arrangements were solely modeled. PV Lighthouse will be presenting a paper on measurements of 2MIP configurations at the IEEE PVSC in July 2020.

Q: Why was the albedo parameter different for 1 MIP compared to 2 MIP in Keith’s study? I believe it was something like 0.240 vs 0.236.

KM: The same albedo was used in the ray tracing of 1MIP and 2MIP configurations. It was a function of wavelength that represents brown, loamy soil. The results of the ray tracing were then used to determine the best value to use as the albedo factor in PVSyst to represent the same soil, and you’re right, it was indeed slightly lower for 2MIP (0.236) than for 1MIP (0.240). This indicates that the 2MIP configuration made slightly less use of the ground-reflected light than the 1MIP configuration over the course of the year (accounting for wavelength, diffuse/direct ratio, and the assumed weather conditions). We expect those values to change for different albedos, module types and conditions.

Q: Is SunSolve already available to simulate bifacial systems? What are the exact outputs of the simulation?

KM: Yes. There are two ways to simulate bifacial systems with SunSolve.

(1) On a contractual basis, where PV Lighthouse performs the simulations (as conducted in this study).

(2) On a subscription basis, where you perform the simulations to determine (i) output power and detailed losses at a single point in time, and (ii) yield, losses and PVSyst inputs over any period of time (available July 2020).

Email support@pvlighthouse.com.au for more detail.

Q: Did PV Lighthouse simulate a 2 MIP configuration to generate similar PVsyst inputs as 1 MIP?

KM: Yes. For the results of the 2MIP configuration, please refer to slide 26 of the webinar, titled “SunSolve – Determine PVSyst inputs,” and the white paper associated with the webinar.

Q: Can you quickly explain again if torque tube shading is significant on a 1 MIP configuration vs a 2 MIP?

KL: PV Lighthouse found that the structural shading loss is not so different for 2MIP and 1MIP. We studied the no-gap case, because we found that a 2MIP configuration with a module gap suffered more losses from the prolonged backtracking than any energy gain from the reduced structural shading.

Q: Is there any method or published article to measure bifacial gain at site?

KL: There is no standardized method. We calculated the bifacial gain by first calculating the daily specific yields of bifacial arrays and a monofacial array and by looking at their ratios.

Q: Is there a need to include back side irradiance in Performance Ratio calculation for the plant?

KL: Cypress Creek, along with NREL, suggested relevant modifications for the capacity testing of bifacial systems in 2019. The publication can be found here.

Q: What is a good resource for determining monthly albedo values?

KL: The best practice would be to make an actual albedo measurement at the site over a year. A fallback solution would be to use albedo values as estimated by various satellite-based services such as PVGIS. NSRDB also offers albedo values.

Q: Is ground-reflected light assumed to have a Lambertian distribution?

KM: Yes, in this study the ground-reflected light was assumed Lambertian. (SunSolve can simulate alternative scattering functions if that is of interest).

Q: Where can I get these ray-tracing derived inputs for running PVsyst simulations?

KM: The results for the PVSyst inputs are on Slide 26 of the webinar and they are also given in the white paper. These results are specific to the particular site (in West Texas) and system configuration. PVSyst inputs for other sites and configurations can be determined with SunSolve.

Q: Where do you all recommend locating an albedometer and backside POA sensor to most accurately represent an entire array?

JC: This depends on exact deployment scenario and how variable the albedo is on the site.

Q: Many bifacial module manufacturers specs or datasheets include a backside gain of up to 25 or 30%. It sounds like realistically the actual “average” or real-world backside gain will be closer to 10%?

KL: It will be closer to 5%.

Q: What is the average production gain over mono-facial modules?

KL: 5-10% would be a good estimate.

Q: Why does an event of high diffuse fraction not translate to increased power production?

KM: An increase in the diffuse fraction leads to an increase in irradiance incident to the rear side of the modules but a decrease in irradiance incident to the front side. That’s why an increase in diffuse fraction leads to an increase in bifacial gain. However, the advantage from the rear side is outweighed by the disadvantage from the front side, except for some rare exceptions like during backtracking very late in the day.

Q: Wouldn’t the gains of 1MIP relative to 2MIP be a wash or negative case considering the additional racking and construction costs associated with 1MIP?

KL: We think 2MIP trackers are still too new to understand the associated costs accurately.

Q: What is the economy of MIP1 v MIP2 in the context of bifacial increase in production using MIP1 v. overall tracker costs (which is presumed less when using MIP2 designs)?

KL: We think 2MIP trackers are still too new to understand the associated costs accurately.

Q: Any work on commercial low slope roof or residential metal roof rooftop applications?

KL: No, this is not an application our product serves.

Q: Would CFV labs be able to release the PVSyst models used for their analysis presented on slide 15?

KL: No.

Q: How dependent are the bifacial gain drivers on the site location? Do these relationships hold equally true in the Northeast and the Southwest U.S.?

KL: It’s complicated. Yes, you’ll see higher bifacial gains in the Northeast compared to the Southwest, but the actual additional energy production in kWh due to bifacial will still be higher in the Southwest.

Q: Is the recommended PVsyst ‘height above ground’ a fit based on the aspect ratio and measured bifacial gain? Would that hold true for all locations?

KL: The study was carried out for a West Texas location. I think you’ll find similar results on other locations, too, but the sensitivity might be different.

Q: Does your testing take into account cell temperature?

JC: We assumed modules were at the same temperature.

Q: Does PV Lighthouse only simulate silicon cells, or can it be used for thin film and/or multijunction cells?

KM: Theoretically, SunSolve can be used to simulate thin-film and multijunction cells, but it is currently oriented toward silicon cells.

Q: Did tested modules have clear gap in the middle of the module so light hits the torque tube and bounces off? Or glazing between cells?

KL: The n-type modules had clear gaps between the cells, but these were full-cell modules. The p-PERC half-cell modules did not have clear gaps.